by Wes Noble

What is UV Curing?

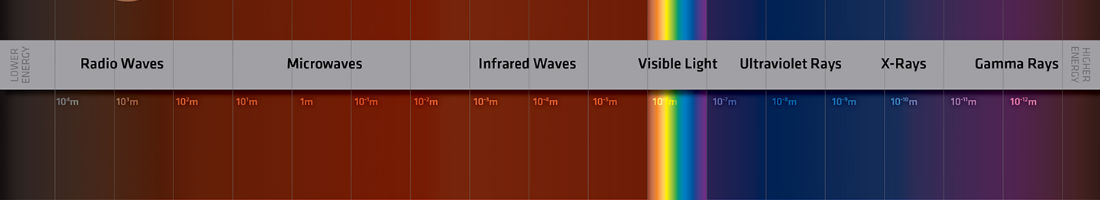

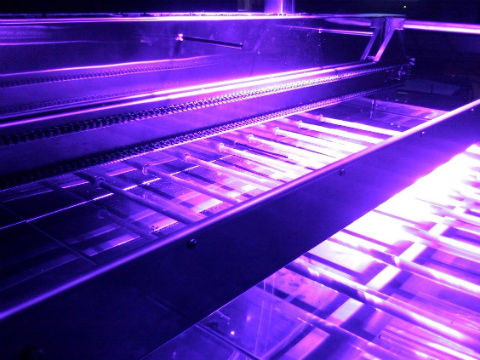

“Ultraviolet (UV) light is an electromagnetic radiation with a wavelength from 400 nm to 100 nm, shorter than that of visible light but longer than X-rays.” (Source: Wikipedia). Ultraviolet or UV curing is used to create a photochemical reaction using high intensity Ultraviolet (UV) energy or “light” to quickly dry inks, adhesives or conformal coatings. Most materials cure with a UV wavelength around 350 ~ 400nm although some materials require UVC energy near 255nm. There are many advantages to using UV curing over other traditional methods of curing. Not only will it increase production speed, it assists in creating a better bond, and improves scratch and solvent resistance. When compared to other methods of curing, UV curing generates a more reliable cured product at a much higher rate of production in a considerably shorter period of time.

Benefits of UV Curing

The benefits of UV curing go further. UV curing produces substantial savings for manufacturers. UV curing processes require less factory real estate compared to curing oven applications that off-gas solvents. This is because the cure time is significantly reduced, requiring less overall space needed for the curing process. UV curing utilizes higher production speeds, and overall makes use of less direct labor. In regards to labor, one of the most recognized advantages of UV curing is its substantial decrease in set-up and clean-up time.

UV curing is environmentally friendly, it requires no evaporation of solvents, so the process produces virtually no emissions. In addition, during the curing process there is no loss of coating thickness or volume. This results in less material waste and lower energy used during production. UV curing is used in many industries for countless applications.

For more information about Ultraviolet (UV) Curing Technology visit ETSMax.com