By: Roger Plough

Measuring Coating Thickness

Achieving an even coat at the right desired thickness is a major challenge when it comes to applying conformal coating to a Printed Circuit Board (PCB). Applying a coating too thin will ultimately render the electronic assembly vulnerable to potential environmental risks therefore defeating the purpose of the coating. Apply the coat too thick, and it could leave the electronic specific components non-functional therefore destroying the electronic assembly entirely. Coating thickness must meet quality specifications. Measurements for coating thickness may be taken while film is dry or wet. Once measurements are recorded, thickness is compared to quality specifications and fluid dispensing automation machinery is calibrated as necessary. There are a handful of methods for measuring conformal coating thickness that are commonly used in the Electronic Manufacturing Services (EMS) and Original Electronic Manufacturer (OEM) industries. A few commonly used methods for checking conformal coating thickness include:

Measuring Coating Thickness Mechanically

Perhaps the most simple method for measuring conformal coating thickness. The circuit assembly is measured (generally using calipers) and known area measurements are recorded before conformal coating is sprayed. After the circuit assembly is conformally coated and dried, it is re-measured in those same areas where measurements were previously taken. The average of these measurements is then taken to determine coating thickness and a standard deviation is used to assess uniformity. If the circuit assembly is conformally coated on both sides, the coating thickness measurement result must be divided by two.

Measuring Wet Coating Thickness

Checking for wet coating thickness entails the use of a wet film gauge. The wet film gauge measures conformal coating thickness while wet allowing operators to test for proper coating thickness before drying. A wet film gauge is a highly precise comb with varying distances between the teeth. The teeth are marked with a measuring range of mils (1/1000’s of an inch). Measuring wet coating thickness is straight forward process. For example, if a wet film gauge with 1-10mils is placed on the coated circuit assembly and the teeth 8 and above have no coating then the conformal coating would be between 7-8 mils in thickness. This measurement is then multiplied by the percent of solid content in the coating (say 35% for Humiseal 1B31) then the cured coating would be roughly 2.45-2.8 mils or 62.23-71.12 microns (1 mil = 25.4 microns).

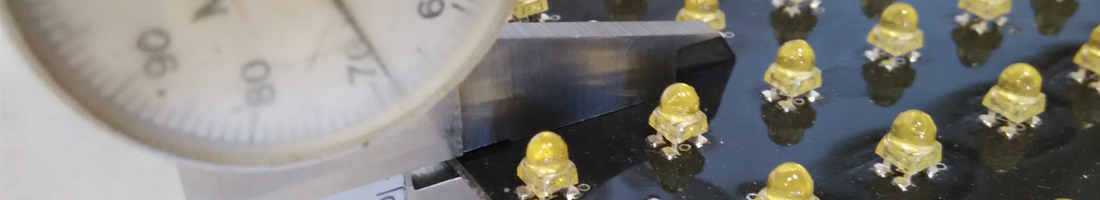

Measuring Dry Coating Thickness

This method of measuring is done when the conformal coating of an electronic assembly is sufficiently dry to handle without causing damage. Measurements can be taken on a PCB’s cured surface or that of a test coupon. Test coupons are non-porous materials such as metal, glass, or preferably the same material as the PCB itself that is sprayed the same as the electronic assembly being manufactured. A test coupon is commonly used as an inexpensive method for calibrating conformal coating thickness for a production run before and after curing. A micrometer or similar accurate measuring instrument is used to check the PCB’s cured coating to quality specifications.