| Curing Mechanisms |  |

|

|---|---|---|

| Ultraviolet (UV) Cure TrioTek™ cure ovens can be equipped with Long Arc, Short Arc, Electrodeless or LED based UV emitters for rapid curing. Long/Short Arc systems offer broad spectral output and high intensity. LED systems utilize focused long wave UVA emitters with a relatively narrow wavelength band for rapid curing. TrioTek’s unique LED emission sources produce very little heat, require no warm-up, emit no harmful UVB, UVC or Ozone, and do not contain Mercury. TrioTek™ LED UV Emitters offer 350mW/cm2 radiant output and greater than 25,000 hours of operation with minimal degradation over time. |

||

| Moisture (Humidity) Cure Many coatings benefit or even require moisture from the surrounding environment in order to cure. Often these coatings can take several hours to cure. In order to accelerate moisture curing, TrioTek™ offers closed loop control of relative humidity within the oven’s process cavity. Humidity levels are monitored, and when required, moisture levels are increased in the supply air prior to entering the process cavity. On-Screen display give the operator instant access to current process cavity relative humidity levels. Thermal (Heat) Cure |

||

| Conveying |  |

|

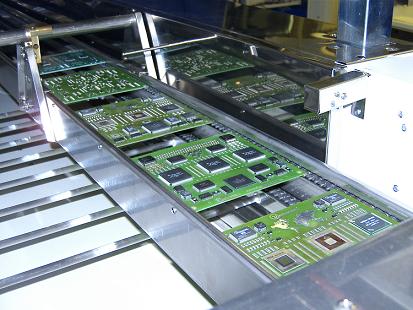

| Edge Grabber™ Conveyor Pin chain carries product through the oven’s process cavity by it’s edges, requiring only 4.5mm (0.177″) under each edge. Pallet Conveyor |

||

| Mesh Belt Conveyor Some applications are better suited by support across the entire width of the conveyor. Can be installed in addition to Edge Grabber™ or Pallet Conveyor. Traffic Control & SMEMA |

||

| Filtration |  |

|

| Supply Air Filtration Air is drawn through large area filters running the length of the machine on both sides to provide clean, fresh air to be used in the process cavity. Pre-Filtration |

||

| Gas Phase Filtration Deep Bed, Gas Phase Adsorbers are employed to remove solvents and odors from the exhaust stream ensuring a safe and comfortable work environment. MERV 10 Filtration |

||