by Brian Stumm

Why Selectively Conformal Coat the Electronic Assembly?

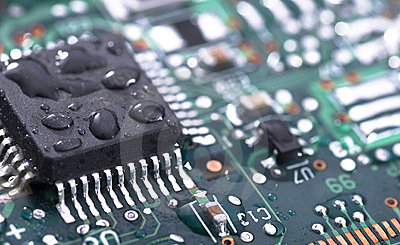

Printed circuit boards (PCBs) are employed in a variety of products and devices, and this means that it might be necessary for your PCBs to be moisture resistant. It is important to choose the right type of conformal coating so you need not worry about the durability of your product. Fortunately, there are several options available that can help, and you can even use selective conformal coating robots to provide proper application of the coating.

Are Conformal Coatings Completely Waterproof?

The purpose of conformal coating is to protect printed circuit boards in harsh environments such as dust, water spray, salt spray, high humidity, and high temperature. It is imperative to have the right coating with adequate water resistant properties if your application requires it – and no single coating is appropriate for all environments. Case in point, a circuit assembly which may see occassional condensation or water spray has lower protection requirements than an assembly which will be submerged in liquid for extended periods. You must consider carefully how the circuit assembly will be employed in order to make an educated choice about the type of coating and application process.

Which Conformal Coating & Application Method Should I Use?

Each type of conformal coating will provide some protection from the environment, but careful review of the coating’s cured properties is essential to having high reliability. In addition, proper application of the coating is needed to ensure successful coating process. Precise, uniform and repeatable application is best suited to robotic, selective conformal coating machines.

Selective Conformal Coating of Electronic Assemblies correctly is part art and part science. A certain finesse is required to avoid keep out areas. It must also be applied uniformly with a high degree of repeatability from one assembly to the next. Without proper setup and programming, even the most precise robotic coating system will fail to meet the environmental demands. A well programmed, precision selective conformal coating robot will offer a quick return on investment in increased yield as well as labor savings.