High Precision Gantry Robot Workcell

FlexCell: Precision Gantry Robot Workcell

Highest Quality Precision Linear Motor Gantry Workcell

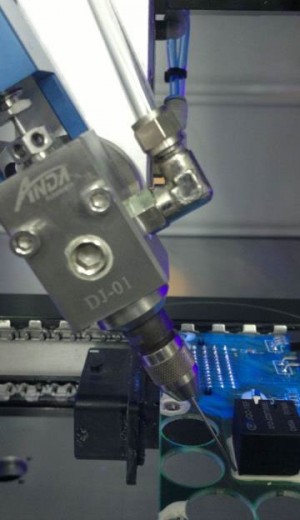

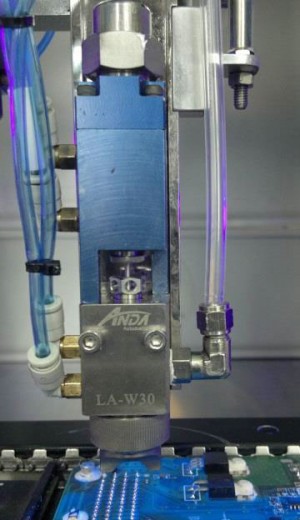

FlexCell is designed to strike a balance between cost and performance. This Multi-Axis, Multi-Head, Linear Motor Robotic Gantry Workcell can be equipped with multiple end effectors such as Selective Conformal Coating Spray and Dispense Valves, Fluid Dispensing Valves, Non-Contact Jetting Valves, Plasma Treatment Nozzles and more.

Additionally, FlexCell can be equipped with dual nozzle simultaneous processing, four direction 35° tilt, valve/nozzle rotation and/or integrated inverter for double sided processing. These features enhance FlexCell performance with the lowest cost of ownership.

Available Features

- Can be configured with any combination of coating, dispensing or plasma nozzles

- PC with LCD monitor, keyboard and mouse (Height Adjustable)

- Auto dipping and purging waste collection system

- LED UV lamps for inspection

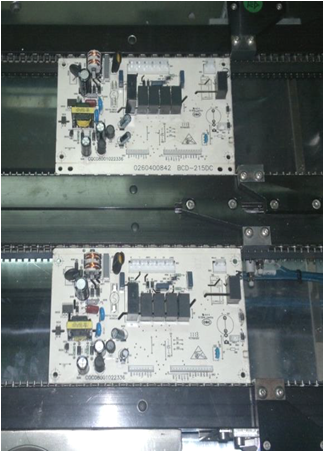

- PCB stopping and clamping system

- 4L material tank (conformal coating)

- UPS and voltage stabilizer

- ESD grounding Point

- Meter Mix System

- CE Certified

- End Effectors can be tilted 35º and rotated 360º

- Heavy duty conveyor

- Dual Lane conveyor system

- 2 stage conveyor

- CCD vision camera

- Material level detection

- Pallet return conveyor (Underneath)

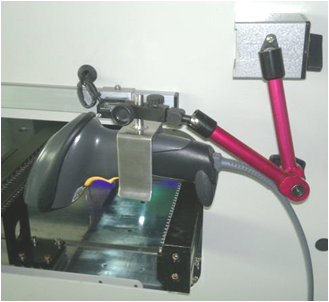

- Barcode or 2D code scanning system

- Coating fluorescence detection sensor

- Substrate heating

- Material delivery heating

FlexCell Specifications

| Facilities | ||

|---|---|---|

| Machine Structure | ||

| Dimension LxWxH (mm) | ||

| Weight | ||

| Input Power | 208VAC Split Phase, 60Hz (4 wire); 208VAC Three Phase, WYE, 60Hz (5 wire); |

|

| Power Consumption | ||

| Compress Air Requirements | ||

| Conveying System | ||

| Conveyor Height | ||

| Speed | ||

| Direction | ||

| Component Clearance | ||

| PCB Edge Clearance | ||

| No. of Conveyors | ||

| PCB Width | ||

| Width Adjustment | ||

| Gantry Robot Motion | ||

| Motor Drive | ||

| Number of Axis | ||

| Linear Motion | ||

| Positioning Accuracy | ||

| Repeatability | ||

| Maximum Speed | ||

| Maximum Acceleration | ||

| Rotation Angle | ||

| Tilting Angle | ||

| Number of End Effectors | ||

| Motion Range | ||

| Selective Conformal Coating | ||

| Conformal Coating Valves |  DJ-01:Needle Valve   LA-W30:Fan Spray Valve  FC-4:Multi-Function Valve  |

|

| Smallest Dispense Diameter | ||

| Smallest Spray Diameter | ||

| Fan Shape Spray Width | ||

| Fluid Dispensing and Jet Dispensing | ||

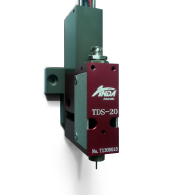

| Dispensing Valves | PV-10: Piezo Jetting Valve PS-8600:Pnuematic Jetting Valve  PS-9200:Pnuematic Jetting Valve  E-01: Electromagnetic Jetting Valve  JET-16: Pnuematic Jetting Valve  TDS-10: Axial Slider Valve  TDS-25: Radial Slider Valve  TDS-40: Radial Slider Valve  LG-02: Electromagnetic Screw Valve  |

|

| Substrate (PCB) Heating | ||

| Valve Heating (Viscosity Control) | ||

| Laser Height Measurement | ||

| Weight Measurement System | ||

| Valve Cleaning System | ||

| Plasma Treatment | ||

| Nozzle Type |  Focused Area: Jet Nozzle  |

|

| Plasma Discharge Width | Tine Jet: 2, 3, 4, 6, 8 or 10mm |

|

| Plasma Discharge Length | ||

[/showhide]

FlexCell Options

Barcode Scanning

Selective Conformal Features & Structures

Complete Line Solution

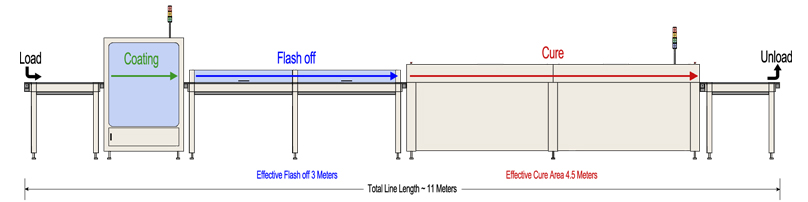

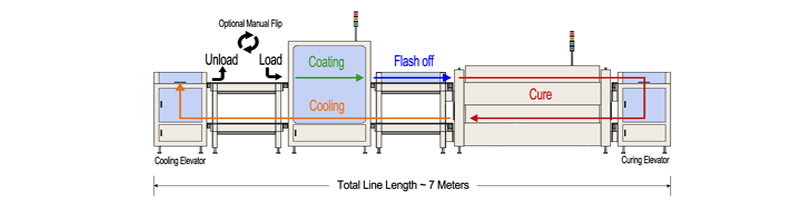

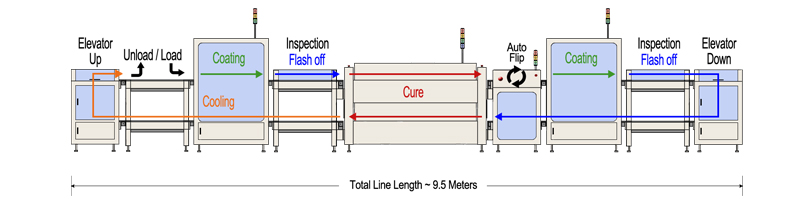

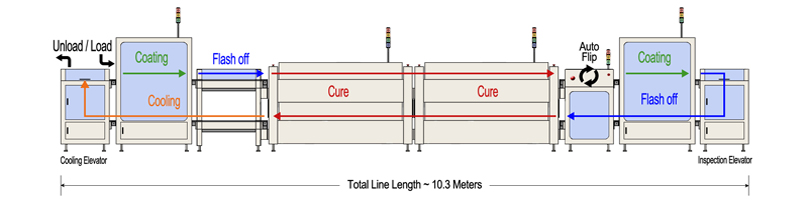

One-Stop Total Line Selective Conformal Coating Solutions provide PCB manufacturers the opportunity to increase their productivity levels exponentially by fully automating their conformal coating process. The example fluid dispensing line below illustrates a 50% reduction in line length over traditional automated conformal coating process lines. Contact Us Today for a specialty coatings system solution using precision dispensing valves, spray nozzles and automation that meets your exact fluid dispensing requirements.

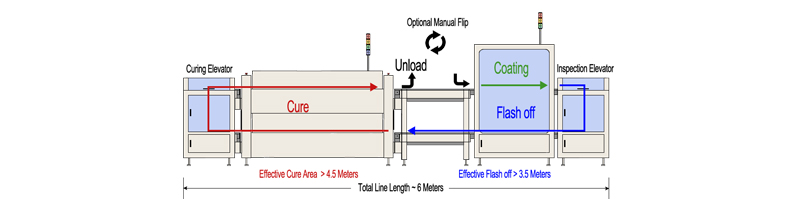

Shown below is a selective conformal coating process line with a single load/unload location. This configuration is ideal for double sided conformal coating while reducing floor space considerably. This selective coating line includes the FlexCell Selective Conformal Coating Workcell, TrioTek Curing Oven, Load/Unload conveyor and Inspection Station. For Pricing and Specifications please Call or E-Mail Us Today!

One Man Operation (OMO) – Fluid Dispensing Line

TrioTek² Thermal Moisture Ultraviolet 2-Level Curing Oven

Traditional vs. OMO

Traditional Line

Traditional or old school process lines have a product flow input at one end and an output at the opposite end of the line. These traditional lines are harder to maintain, require more labor, and occupy greater factory space.

OMO Line

OMO has several advantages over traditional process lines. Product flow input and output occurs at the same location allowing for a convenient manual flip for coating or dispensing on both sides of a PCB assembly. In addition, a single operator can both load and unload the PCB assemblies for the entire line reducing labor costs. This also reduces handling time and the number of pallets needed for manufacturing processes of PCB assemblies. Depending on the process line, an OMO line has a reduced factory foot-print of up to 50%. In an ideal environment, it could nearly double the production capacity of a manufacturing facility.