Controls, Hardware & Software

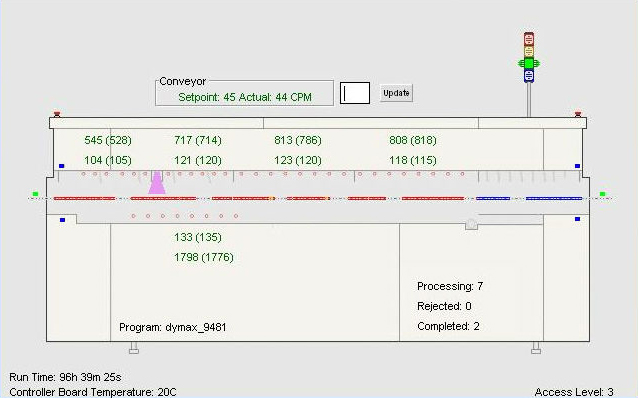

To achieve lowest possible cost, highest performance, and highest reliability, ETS employs distributed controls concepts to maximize flexibility, reliability, modularity and usage in all factory automation offerings. One such example is the ETS Wattage/Temperature Controller. A miniature PCB that provides PID, closed loop control of both Wattage and Temperature for a single heating zone. Several ETS developed electronic devices are used within our Factory Automation Systems or offered independently as stand alone products. Each Factory Automation Machine has a dedicated Single Board Computer (SBC) and at least one I/O HAT. Thermal Systems utilize one Zone Controller for each heat zone. Communication between SBC and distributed controllers is accomplished via the RS485 bus.

All software is written in POSIX Compliant ANSI C to enable maximum compatibility with potential third party software and to ensure cross-platform compatibility (Microsoft, Macintosh and Unix Variants). It is often practical to employ a single User Interface to control an entire factory automation line from a central location. Through the ETS developed API, commands can be passed over Ethernet or Wifi to the single board computer allowing setpoints to be updated on the fly from other Human Interfaces such as a Windows PC or Laptop.