By: Brian Stumm

5 Axis Fluid Dispensing

Technology is in constant change and circuit assembly is no different. It is becoming more and more advanced as needs change and demands for more capabilities increase. In order to meet these demands, equipment manufacturers are integrating the latest innovations and tools to serve the industry. The need to better protect printed circuit assemblies from harsh environments using automated selective conformal coating is becoming a must. 5 axis fluid dispensing allows conformal coating to be applied to printed circuit assemblies like never before.

What is 5 Axis Fluid Dispensing?

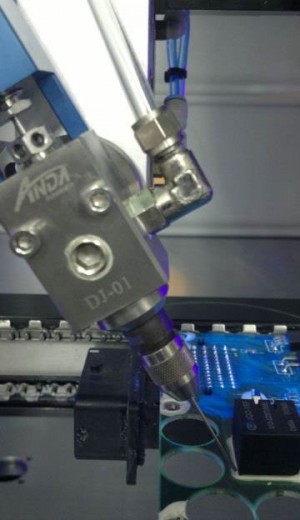

5 axis fluid dispensing combines tradition four-axis (X, Y, Z, U or ±180˚rotation) with the added tilt functionality. This method of fluid dispensing allows for conformal coating to be applied selectively to the bottom and sides of electrical components where it was not previously possible using automation. Further, this technology allows for dispensing on vertical components, underneath (capillary underfill), and in all those nearly impossible to reach places. This is done with the highest level of precision and provides an entirely new level of protection for electronics.

It’s the added tilt functionality that really makes these changes in fluid dispensing and selective conformal coating possible. The fluid dispensing valve or nozzle now has the ability to tilt to a maximum of ~35˚ using this capability. Now when combined with rotation, the fluid dispensing or selective coating machine can reach the front, back, and both sides of a component for most applications. Underfill applications also benefit from tilt and rotate fluid dispensing.