Plasma Treatment Systems

What is Plasma Treatment?

Atmospheric plasma treatment is a unique technology for surface treatment in electronic assembly, Nano-Cleaning, Removal of Organic Contaminants, Surface Activation/Modification, Surface Ablation and Etching, Hydrophiling, Passivation, Hydrophobing, and Biocompatibility of almost all materials – composites, plastics, metals, glass, cardboard, textiles, etc. With ETS plasma technology, plasma surface treatment can be inserted inline with fluid dispensing or selective conformal coating. ETS also offers vacuum plasma for thin film chemical deposition coating.

By means of a high-voltage discharge (5–20 kV, 10–100 kHz) a pulsed electric arc is generated. A process gas, usually clean, dry compressed air flowing past this discharge section, is excited and converted to the plasma state. This plasma then passes through a jet nozzle to arrive on the surface of the material to be treated. The plasma nozzle is at earth potential and in this way largely holds back potential-carrying parts of the plasma stream. In addition, it determines the geometry of the emergent beam. Since Plasma is produced under a high voltage discharge environment an ordinary plasma nozzle exhibits blow out or arcing at the tip which may contact the electronic assembly resulting in damage to sensitive components. ANDA Plasma treatment nozzles offer a “current absorption loop” to eliminate the high voltage arc at the discharge cavity and safely treat sensitive electronics.

Plasma treatment removes contaminants while providing surface modification which facilitates adhesion of various coating materials. Additionally, plasma surface treatment promotes the flow of coating for thin film coating without other mechanical or chemical treatments required.

How Does Plasma Treatment Work?

The atmospheric plasma surface treatment system is composed of the plasma generator, compressed gas delivery, and plasma nozzle. High pressure gas and high frequency energy generates low temperature plasma through activated and controlled discharge in plasma head. With compressed air or gas directing the plasma to the surface of the product.

Benefits of Plasma Treatment for Surface Modification

- Better surface coverage and spreading of coatings enhancing bonds between surfaces

- Improve uniformity of coating thickness over the surface of the substrate

- Increases surface energy of a substrate improving wettability or the ability for liquids or coatings to “wet out” over the surface

- Render a surface hydrophilic (improve wetting) or hydrophobic (repel/avoid wetting) with the appropriate process gas(es)

- Selectively change surface properties without changing the entire substrate or material

- Prepare surfaces for subsequent processing, e.g. film deposition or adsorption of molecules

PT Coater Plasma Treatment & Coating Machine

The revolutionary PT Coater combines both Plasma Treatment and Conformal Coating into a single Automated Workcell:

It is mainly used for PCB Selective Coating as well as Display Screen, Touch Screen and Glass Coating. The PC Coater combines both Plasma Treatment and Conformal Coating into a single machine workcell. A substrate is plasma treated prior to coating to ensure better wetting, surface coverage, bonding, etc. The PT Coater is an effective cost solution to buying separate plasma and coating machines and occupies less factory floor space in an assembly line.

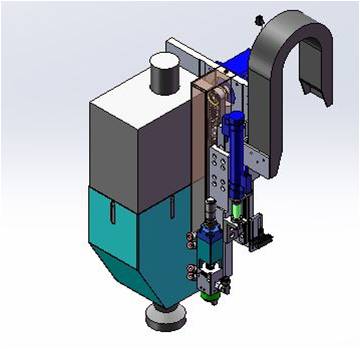

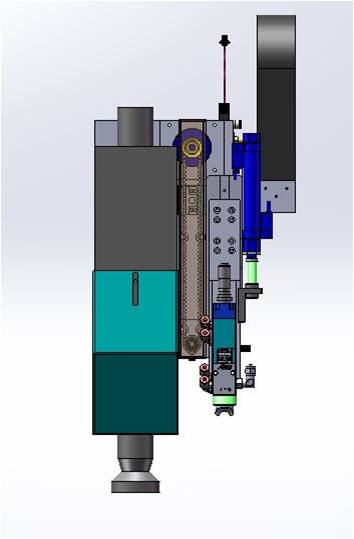

PT Coater Machine Plasma Nozzle & Valve Configuration

PT Coater Plasma Treament & Conformal Coating Machine Specifications

Coating

| Power & Factory | |

|---|---|

| Machine Structure | |

| Dimension LxWxH (mm) | |

| Weight | |

| Input Power | 208VAC Split Phase, 60Hz (4 wire); 208VAC Three Phase, WYE, 60Hz (5 wire); |

| Power Consumption | |

| Compress Air Requirements | |

| Conveyor | |

| Conveyor Height | |

| Speed | |

| Direction | |

| PCB Edge Clearance | |

| No. of Conveyors | |

| PCB Width | |

| Width Adjustment | |

| Motion | |

| Drive Mode | |

| Number of Axis | |

| Linear Motion | |

| Positioning Accuracy | |

| Repeatability | |

| Max Speed | |

| Plasma Treatment | |

| Nozzle Type |  ;Focussd Area: Spear Tip Nozzle ;Focussd Area: Spear Tip Nozzle |

| Number of Plasma Nozzles | |

| Plasma Processing Width | |

| Plasma Discharge Length | |

| Travel | |

| Coverage Area | |

| Component Clearance | |

| Standard Valve |  |

| Optional Valves |  ; DJ-01:Needle Valve ; DJ-01:Needle Valve ; DJ-03:RTV Silicone Needle Valve ; DJ-03:RTV Silicone Needle Valve ; FC-4:Multi-Function Film Valve ; FC-4:Multi-Function Film Valve |

| Number of Coating Valves | |

| Travel | |

| Coverage Area | |

| Component Clearance | |

| Smallest Dispense Diameter | |

| Smallest Spray Diameter | |

| Fan Shape Spray Width | |

| Rotation Angle | |

| Tilt Angle | |