One Man Operation (OMO) – Conformal Coating Line

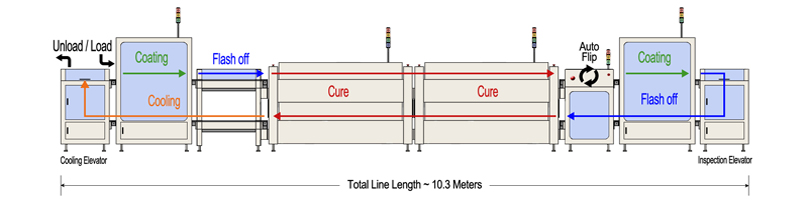

One-Stop Total Line Selective Conformal Coating Solutions provide PCB manufacturers the opportunity to increase their productivity levels exponentially by fully automating their conformal coating process. The example fluid dispensing line below illustrates a 50% reduction in line length over traditional automated conformal coating process lines. Contact Us Today for a specialty coatings system solution using precision dispensing valves, spray nozzles and automation that meets your exact fluid dispensing requirements.

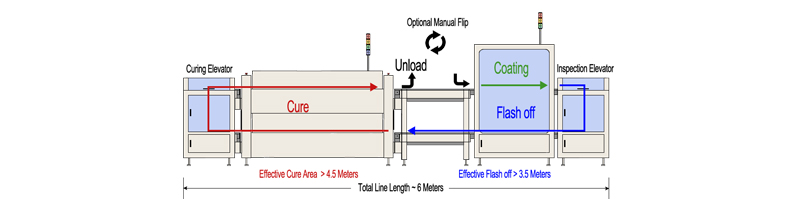

Shown below is a selective conformal coating process line with a single load/unload location. This configuration is ideal for double sided conformal coating while reducing floor space considerably. This selective coating line includes the iCoat Selective Conformal Coating Workcell, TrioTek Curing Oven, Load/Unload conveyor and Inspection Station. For Pricing and Specifications please Call or E-Mail Us Today!

One Man Operation (OMO) – Fluid Dispensing Line

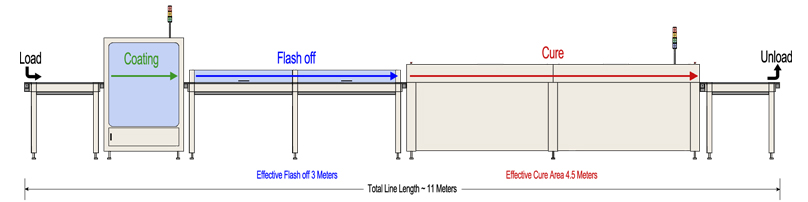

Traditional vs. OMO

Traditional Line

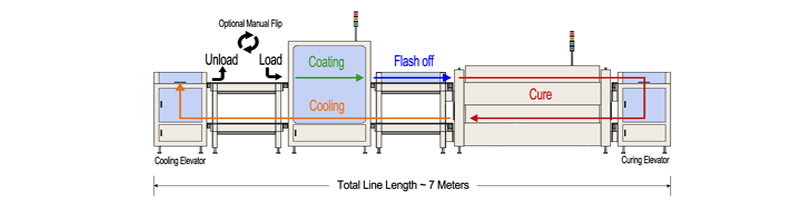

OMO Line

OMO has several advantages over traditional process lines. Product flow input and output occurs at the same location allowing for a convenient manual flip for coating or dispensing on both sides of a PCB assembly. In addition, a single operator can both load and unload the PCB assemblies for the entire line reducing labor costs. This also reduces handling time and the number of pallets needed for manufacturing processes of PCB assemblies. Depending on the process line, an OMO line can reduce up to 50% of the space required for a traditional line virtually making it possible to double the capacity of any manufacturing facility.