Heating & Thermal Energy Transfer

Convection with Soft Infra-red for Reflow and Preheating Applications

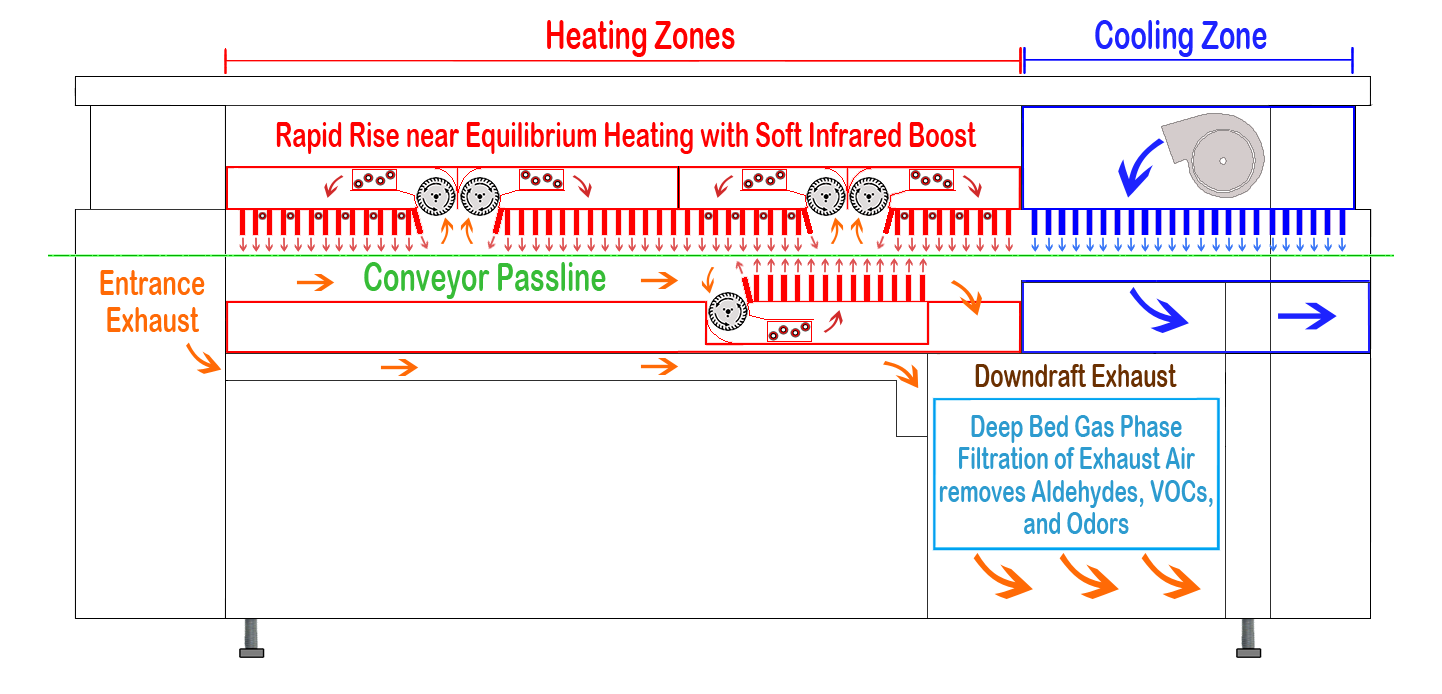

ETS optimizes thermal energy transfer to electronic assemblies through its unique combination of Convection and soft Infra-red heat delivery systems. Infra-red “boosters” provide quick temperature acceleration to high thermal mass components or ground planes while Recirculating Hot Air (RHA) blowers maintain even temperature to all areas of the assembly. Low mass coil heating elements provide quick response for varying production loads ensuring process repeatability. Recycled and Cascaded air is drawn from the low thermal mass process cavity with tangential blower wheels running the full width of the process cavity for even airflow.

The air is heated and forced through nozzles onto the product. Columnized air retains its direction and velocity resulting in maximum impingement velocity on the product, high energy transfer and Near Equilibrium Heating™. Air is cascaded from one zone to the next reducing energy consumption.

The video illustration below demonstrates the (ETS) Rapid Rise Near Equilibrium Heating System: Airflow is drawn (recycled) from the process cavity by the tangential blower wheel, passes across the low mass coil heating element, pressurizes in the heat plenum and impinges onto the product via the impingement nozzles. Infra-red heat boosters are positioned between the rows of impingement nozzles.

Rapid Rise Near Equilibrium Heating System

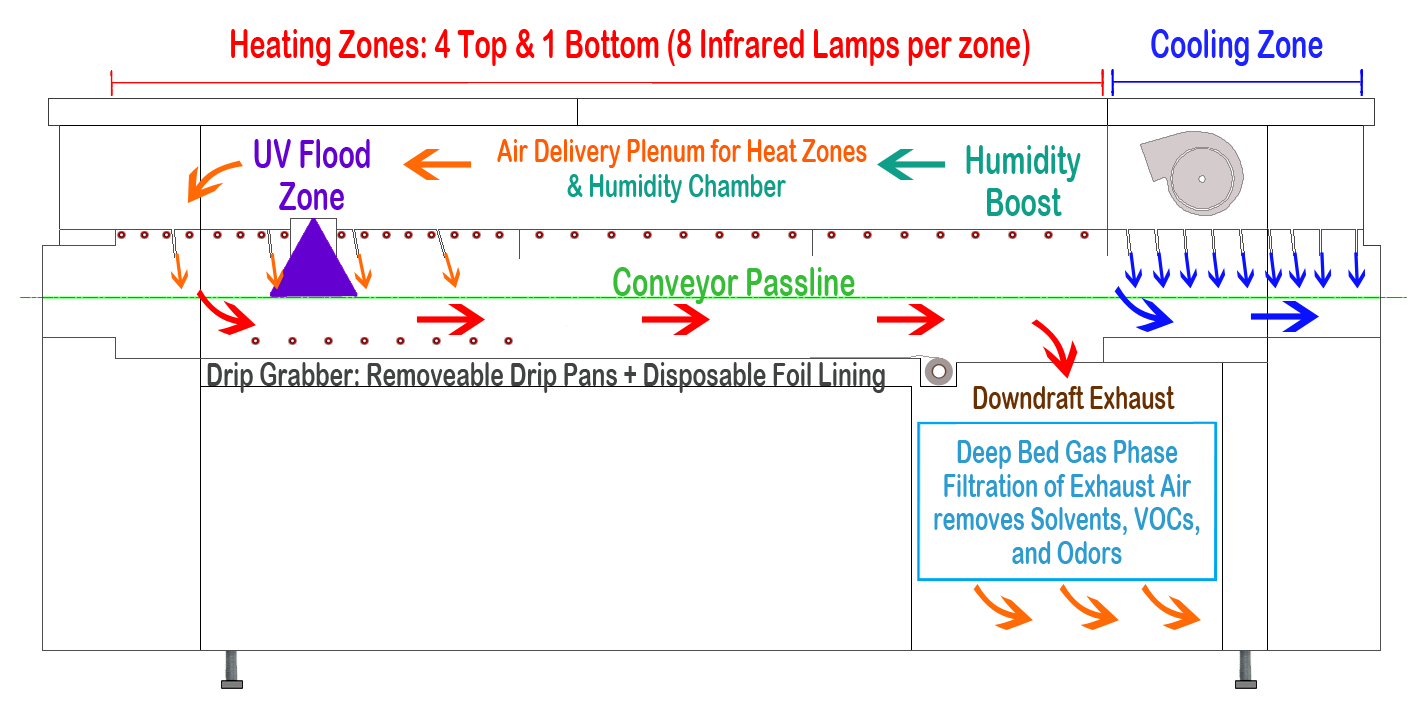

Infra-red with Soft Convection for Curing Applications

The primary method of heat transfer is combination convection and long wave Infrared (IR). Convection warming is accomplished by first pressurizing a plenum above the curing oven’s process cavity, second directing the air to the first two zones and then through air knives in the hot plates to the product. Air temperature is slightly higher than ambient, promoting off-gasing of solvents. Long wave Infrared (IR) emitters heat and cure coatings from the inside out. This combination of heat delivery eliminates problems associated with surface skinning and solvent off-gassing.