Advanced Exhaust & Filtration Systems![]() European Council (EC) Solvent Emissions Directive (SED) Compliant

European Council (EC) Solvent Emissions Directive (SED) Compliant![]() Qualifies for LEED Indoor Environmental Quality (IEQ) Credits

Qualifies for LEED Indoor Environmental Quality (IEQ) Credits

ON-BOARD POINT OF USE EXHAUST FILTRATION

xFlow™ Exhaust Controller

PID Closed Loop Control of Mass Air Flow employs a rotary, motorized damper and air flow sensor to monitor and regulate exhaust flow rates to user specified setpoint. Maintains lower than 25% LEL (Lower Explosive Limit) for solvent based processing. Reduces loss of factory conditioned air. Increases process control and repeatability. Detects clogged filters and other out of tolerance process parameters.

Supply Air Filtration

When applicable, 30 PPI Reticulated Foam Filtration or better is employed for air consumed by the factory automation process. Air is drawn through large area filters to provide clean, fresh make-up air.

Pre-Filtration

Course filters are used in the exhaust to protect more expensive secondary filters from premature dust and contaminant loading ensuring long filter life and less frequent replacement.

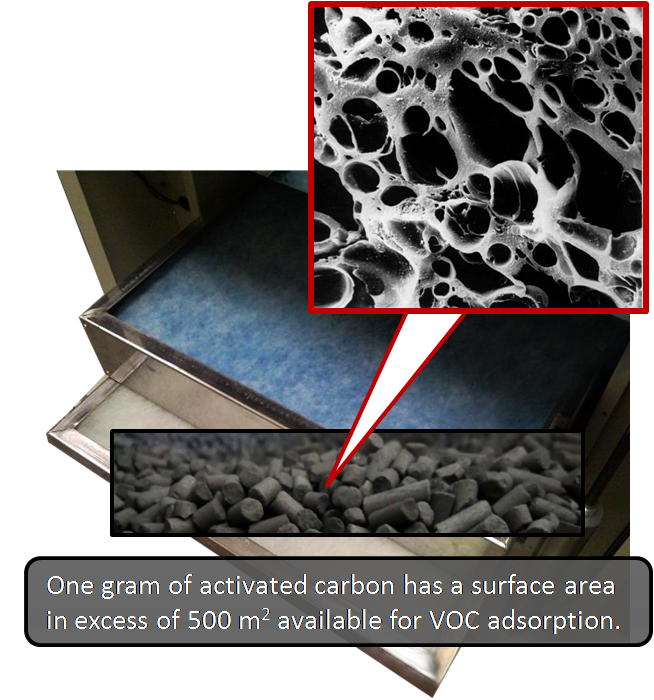

Gas Phase Filtration

Deep Bed, Gas Phase Adsorbers are employed to remove solvents and odors from the exhaust stream ensuring a safe and comfortable work environment.

MERV 14 Filtration

(~95% efficient, particles ≥ 0.4 micron) Minimum Efficiency Reporting Value, 10 or greater. Highly efficient filtration for removing particulates in the 0.4 to 3 (and larger) micron range offers LEED® credits. (IEQ Credit 1.4)

HEPA Filtration

(>99% efficient, particles ≥ 0.3 micron) High-efficiency particulate absorption or HEPA is a type of air filter available as an option for all ETS manufactured factory automation systems. Filters meeting the HEPA standard have many applications, including use in medical device manufacturing, semiconductor and cleanroom. To qualify as HEPA, an air filter must remove (from the air that passes through) 99.97% of particles that have a size of 0.3 micron or larger.