Conveying and Product Handling

TraffikFlow™

TraffikFlow™ verifies the time element of the factory automation process, and controls the passage of product between other upline or downline equipment. The space between products is programmable. Photoelectric sensors monitor the passage of product into, through and out of the factory automation system. The information is used to detect jammed, missing or extraneous product, thus preventing damage. Actions from a caution light to an emergency shutdown will automatically occur as appropriate. Fully SMEMA compliant.

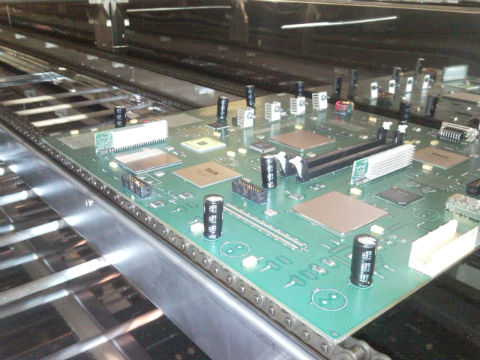

Edge Grabber™

A fully programmable, adjustable width, self calibrating conveyor system, which will support products directly from other processing equipment in an automated manufacturing environment, including pick and place, dispensing and board handling devices. Large clearances above and below the product, along with minimal edge interference, qualify the Edge Grabber for both single and double-sided processes. For further flexibility and to optimize throughput ETS can configure Factory Automation Systems with multiple Edge Grabber Conveyors for multi lane processing. Pin chain carries product by it’s edges, requiring only 4.5mm (0.177″) under each edge.

Pallet Grabber™

For heavy and/or palletized products, ETS recommends the pallet conveyor where product rides atop the chain, requires 15.9mm (0.625″) on each edge of the pallet. Motor torque is increased to deal with high loads. Similar to the Edge Grabber™ Conveyor but designed for higher loading, up to 20lbs per linear foot. Multi lane processing and auto-width adjust are also available in this conveyor design.

Mesh Belt

Whether the only conveying system, or combined with the Edge Grabber™, the Stainless Steel Mesh Belt operates from end-to-end of the system, a feature unique to ETS. This eliminates the need for additional conveyors between the thermal processing system, ultraviolet curing system or material handling system and other manufacturing equipment in the assembly line. ETS employs low thermal mass stainless steel wire mesh conveyor material using gravity tensioning for long operating life. Various material sizes are available to meet various product sizes and weight, no matter how small or large.