Modular Factory Automation Systems

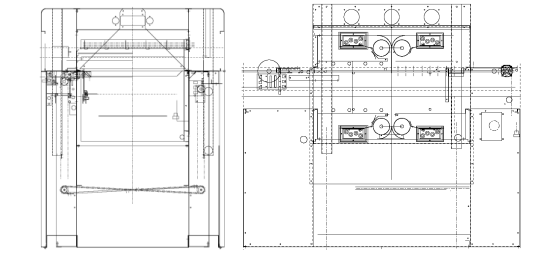

Configuration and Size

Pass line height is SMEMA compliant, 38 to 39 inches. Standard systems are capable of handling up to 20 inch wide product on the patented Edge Grabber™ Conveyor, Edge Grabber™ Pallet Conveyor or mesh belt. The Edge Grabber™ conveyor width is manually adjusted. Auto Width Adjust option is available. Product Clearance is 1.75 or 3.5 inches above and below the product pass line depending on application requirements. Available Power Configurations are 208Volt, 380Volt, 420Volt, 480Volt 3φ Wye (5 wire) 50 or 60Hz for Thermal Process Systems and 120 or 230VAC 50 or 60Hz for other systems.

System Construction

ETS Factory Automation Systems are modular in design. Manufacturing cost is minimized to create variable length systems which all incorporate the same robust design. Using this modular design theory, ETS quickly and easily designs application specific products to meet your need. System Controls are accessible from either side of the users assembly line.ETS Factory Automation Systems utilize unibody construction, making them stronger than machines with large, heavy frames. Large Area Filters offer long life and easy, on- the-fly replacement.

Components and Assembly

Modular Construction, as described above, decreases build cycles and manufacturing costs. Most sheet metal components are used in other ETS products. All sheet metal parts are 13ga. or 16ga. cold rolled steel and all are designed, manufactured and finished at ETS. The process cavity is completely constructed from 400 series stainless steel. Almost all (90%) machined parts are designed and manufactured at ETS. Many components are inventoried in sub-assemblies to decrease specific, final configuration lead times. Final assembly, turn on, run, test and process test are conducted to exacting documented procedures to verify performance, reliability and repeatability.

Wiring and Electrical Components

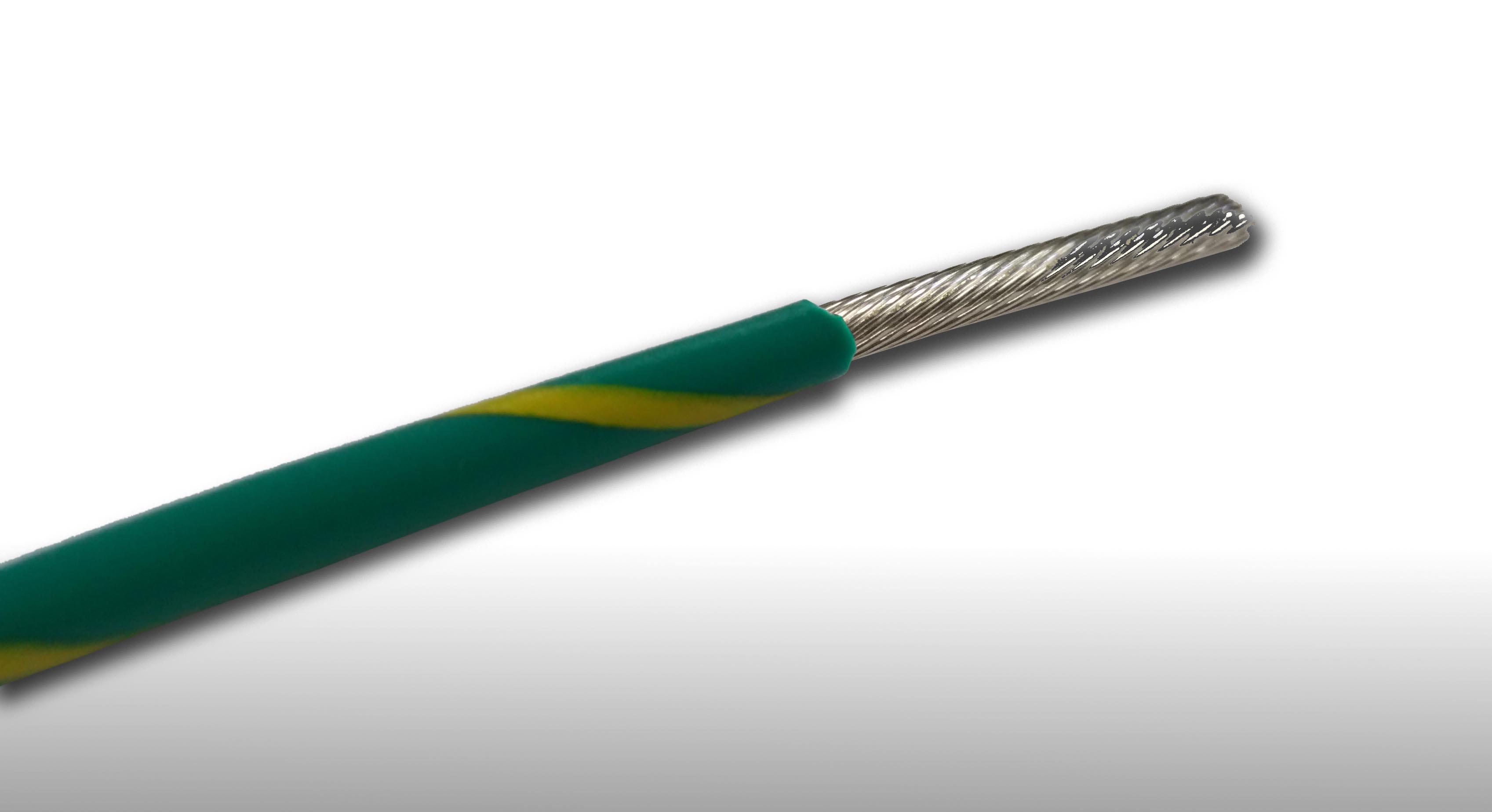

ETS Factory Automation Systems have several wiring harnesses, each of which is documented and constructed to applicable industrial standards. The harnesses include voltage distribution, controls, motors, and thermocouples. Within these harnesses, individual wires are color-coded as:

Red = AC

Blue = DC low voltage

Black = AC Switch

White = Neutral

Green/Yellow = Ground

Shielded cables are used where applicable to reduce noise emissions and susceptibility. All thermocouples are shielded with the shields grounded to the machine ground block. For board protection from static electricity, static ground jacks are located near where circuit boards can be accessed. In addition to the wiring harnesses described above, each system has a high temperature wire harness for the high voltage power to the heating elements. Wherever possible, this harness is routed separate from the low voltage control wiring to minimize electrical interference. The high temp wire harness is color-coded black for the hot wires and light blue for the neutral wires. Neutral wires are labeled with ‘N’ near the heater element termination. The modular electrical panel has an integrated heat sink and is inventoried as a sub-assembly. All purchased electrical components are readily available and meet industry standards. ETS offers a unique main power disconnect handle, which may be accessed, and/or safety locked from either side of the process line. All electrical access covers are labeled, require tools to remove and/or are safety interlocked to the main disconnect handle. All electrical components and wires are labeled and easily accessible. Emergency stop buttons are easily accessed from either side of the machine.